What are Perforated Boxes?

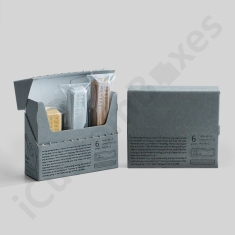

Perforated packaging boxes are specially designed packaging with small cuts or slits. These cuts allow airflow, easy opening, or product display. They protect the product, improve customer experience, and make handling, shipping, and retail display easier.

What Makes Custom Perforated Packaging an Ideal Choice?

The perforated boxes impression remains in the customer’s mind for a long time. They remember the brands that offer stress-free and easy access to products.

Our perforated dispenser boxes are an ideal choice for making your customers happier. They protect, display, and deliver your products efficiently. This is a one-of-a-kind box that can cater to all your packaging needs.

One of the most significant benefits of perforated box is its simple design with tiny cuts to open the box easily. Instead of struggling with scissors or risking product damage, customers or retailers can follow perforated lines.

Hence, the smooth opening makes our custom perforated boxes the favorite.

Our versatile product packaging boxes elevate your brand and impress buyers. The unique designs with perforation give products an immense appeal. Additionally, we utilize top-class printing technology to establish a strong brand identity. You can ask us to design them to meet your specific business needs.

Why Do Businesses Like Perforated Packaging Boxes?

The multifunctional custom perforated packaging always remain in demand. Their user-friendly style and creative designs impress product manufacturers.

Customers are also fascinated by the convenient and interesting product packaging. Here are many other reasons that also make these boxes preferable.

- Fast and straightforward opening experience.

- Prevents product damage during Unboxing.

- Works for both storage and retail display.

- Promote your business and bring immediate sales

- Safe custom design perforated boxes to reduce your brand's carbon emissions.

Types of Perforated Boxes We Offer

Every product needs a different style of perforation, airflow, and opening experience. That’s why we offer a full range of perforated box types. Each style focuses on a specific function—ventilation, access, display, or protection. You get packaging built for your exact product and your exact workflow.Perforated Shipping Boxes

Shipping boxes use carefully placed perforations that maintain strength. You get controlled airflow, clean opening tabs, and reliable structure for transport.

Ventilated Produce Boxes

These boxes include patterns that support fresh produce during long trips. Air passes through the product naturally and reduces heat and moisture.

Tear-Strip Mailers

Mailers with tear strips give your customers instant access. They skip knives and scissors, which protects both the user and the product.

Retail Display (Shelf-Ready) Boxes

Store staff remove perforated sections and place the box directly on shelves. These custom display boxes reduce labor time and helps products sell faster.

Perforated Sleeves & Wraps

Sleeves add airflow and visibility around multipacks. They work well for bakery items, produce, cosmetics, and promotional bundles.

Windowed Boxes

Window perforations frame your product for instant visibility. These designs increase trust and make your packaging more attractive.

Subscription Tear-Open Boxes

Subscription brands use these for a smoother unboxing moment. The perforation controls how the customer enters the box and sees the product.

Perforated Inserts & Dividers

Inserts use micro-cuts or tear lines for easy folding and product access. They keep items organized without slowing down packing teams.

Choose Premium Packaging Material Options

We offer a variety of materials, including cardboard, kraft paper, and corrugated stock. Cardboard is ideal for light objects and your brand publicity. Custom cardboard boxes allow you to create any design, color, or artwork.

Meanwhile, Kraft paper is also available to support your brand sustainability goals. The other choice is corrugated cardboard, which is ideal for heavy or delicate products. You can choose this option if you require extra protection during delivery.

High-Quality Printing Services with CMYK & PMS Colors for Eye-Catching Packaging

Our high-quality printing helps you make your brand more recognizable.

Custom-printed perforated boxes with a brand logo capture the attention of a wider audience.

You can add product or brand information on perforated flaps to give a unique look. With bold, colorful themes, we let you shine on shelves. The CMYK or PMS color options expand your visual options and enhance brand visibility.

Select an appropriate printing method to create a strong shelf look.

Give a Premium Touch to Your Packaging with Finishing Options

If it ends well, then all is well. This phrase is accurate in a perforated box packaging. Customers notice the refined look of your artwork and design. This gives them an idea of your brand quality and product value. Thus, we offer you a range of options to make your brand both prominent and elegant.

- Gloss lamination

- Matte Lamination

- Aqueous Coating

- Spot UV

- Foil Stamping

- Embossing

- Debossing

- Size and Shapes

We design customized shapes and sizes of boxes to meet your exact requirements. Whether it's a small retail or a large shipping box, our team ensures a perfect fit with clean holes for easy use.

Why Choose us for Affordable Custom Perforated Boxes?

iCustomBoxes is the best place to buy affordabel perforated boxes wholesale at low prices.

We use durable materials that keep products safe in all conditions. Our high-class printing gives you an edge over others. Enjoy the following perks with us.

- Free Delivery across the USA

- Fastest Turnaround time

- Quality Assurance

- Free Quotations

- Quick Shipping

- 24/7 live chat facility

- No MOQs

Place an order of custom perforated boxes and start customization.