- Home

-

By Industry

- Custom Retail Boxes

- Custom Cardboard Boxes

- Custom Cosmetic Boxes

- Custom Food Boxes

- Custom Gift Boxes

- Custom Display Boxes

- Custom Mailer Boxes

- Custom Paper Bags

- Custom Sports Boxes

- Custom Stationery Boxes

- Custom Bakery Boxes

- Custom Gable Boxes

- Custom Tuck Boxes

- Custom Pillow Boxes

- Custom Cupcake Boxes

- Custom Donut Boxes

- Custom Burger Boxes

- Custom Chocolate Boxes

- Custom French Fry Boxes

- Box by Style

- Custom Packaging

- Our Products

- Request Quote

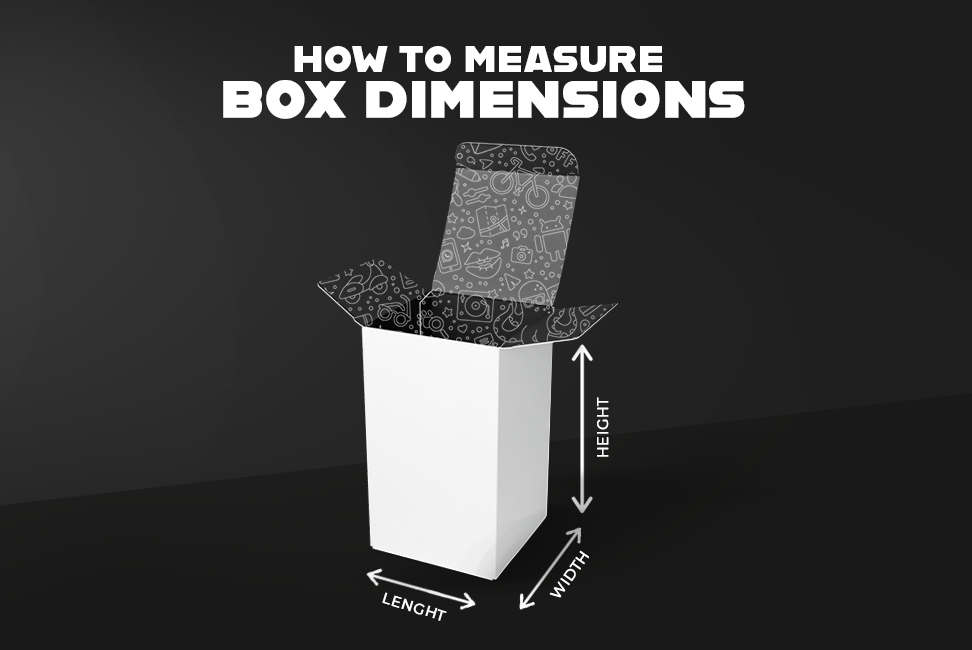

How to Measure Box Dimensions Correctly

- Why do you need to measure box dimensions properly?

- Understanding Box Dimensions

- Inside vs Outside Dimensions — The Critical Difference

- General Terminology for Box Dimensions

- Step-by-Step Guide: How to Measure a Box

- Recommend the optimal packaging size

- Types of Boxes and How Measurements Differ

- Measurement Units & Conversion Chart

- How to Choose the Right Box Size for Your Product?

- Common Measurement Mistakes to Avoid

- Impact of Box Dimensions on Shipping

- Dimension weight: calculated as (length × width × height) ÷ DIM divisor.

- Custom Box Dimensions: What Makes It Ideal?

- How to Get Accurate Custom Box Measurements?

- Common Mistakes to Avoid When Ordering Custom Boxes

- Conclusion

- Frequently Asked Questions:

When it comes to packaging, the exact box dimensions can create all the differences. Whether you send products, organize storage, or customize packaging, it is necessary to know your boxes' exact length, width, and height.

Exact measurements improve packaging efficiency, reduce waste, minimize shipping costs, and ensure safety. It delivers products to customers safely and in the right position. An extra few centimeters or inches can also give birth to incorrectly damaged goods. Also, it brings high shipping fees or dissatisfied customers.

This guide teaches you how to measure the box dimensions correctly. You will also learn how this affects everything from safety to your lower line.

To measure a box dimension, identify the top opening, then use a measuring tape to record the length (longest side), width (shorter side), and height (from top to bottom). Multiply L x W x H to calculate volume.

Why do you need to measure box dimensions properly?

Measuring your boxing dimensions accurately provides many important benefits:

1. Choose the right box for your product:

Whether working on a small rectangular box or a large container, the exact size helps you choose packaging that fits as gloves.

2. Reduce waste and optimize storage:

Make sure the correct dimensions will save you from waste of material and space.

3. Reducing shipping costs:

The shipping fee is calculated based on packaging weight. So, an oversized box can increase the shipping cost.

4. Protecting your products:

A large box can cause the item to move inside. Meanwhile, a box of a very small size can cause damage due to the limited space.

5. Increasing customer satisfaction:

Well-packed products come safely and leave a professional impression.

Understanding Box Dimensions

What are the box dimensions?

Box dimensions are usually expressed as length × width × height. Let's break it:

Length: The longest side of the box.

Width: Small side, vertical length.

Height/depth: When the box is upright, the vertical dimension is measured.

These three measurements define the size of the box and determine how much space it will take. Box dimensions are shown in centimeters or inches, depending on what you measure.

Inside vs Outside Dimensions — The Critical Difference

One of the most frequent mistakes is conflating internal (inside) and external (outside) dimensions. They each serve different purposes:

Inside dimensions:

The usable interior space. This is the size that your product and padding must fit into. For instance, if you have a gadget that’s 8" × 5" × 2", you need the interior to at least match that (plus extra room for cushioning).

Outside dimensions:

The total size of the flat box, including wall thickness, fluting, and folded edges. Carriers use external dimensions to assess space, fit, and shipping cost.

The difference matters because wall thickness, especially for corrugated materials, can take up ⅛" to ⅜" or more on each side. If you design entirely by external size but forget wall thickness, the product might be too tight internally.

Also, when quoting custom boxes, suppliers often ask for “inside dimensions” to ensure product fit, but when shipping, you’ll deal with external dimensions.

General Terminology for Box Dimensions

Here is a quick terminology for box dimensions:

- Length: The Top opening when you look at the top opening.

- Width: Small edges perpendicular to length.

- Height (or depth): Steals up to the base.

Different industries may prefer these measurements in various ways, but the sequence is usually the same: length × width × height.

Step-by-Step Guide: How to Measure a Box

Here is how to measure both empty boxes and ones with goods inside. Be consistent in measurement orientation.

Tools You’ll Need

- Measuring tape (rigid, preferably)

- Ruler or steel ruler

- Calipers (for tighter tolerances)

- A marker or pen to note which sides are which

Software For Measuring Box Dimensions

Many packaging design programs help you to measure box dimensions. It allows you to:

- Create a virtual boxing model.

- Like how the products fit.

- Calculate dimensions automatically.

- In addition, you can go with the online box measurement calculator. This equipment

- Help to estimate the shipping fee

Recommend the optimal packaging size

Step 1: Identify the box opening

Open the box so the top flaps are laid open; now you see the open mouth.

Step 2: Measure Length

Take the longest opening side. Measure from inside edge to inside edge (for internal dimension), or from outer edges (for external). Write that down.

Step 3: Measure Width

Measure the shorter opening side, again inside-to-inside or outside-to-outside as needed.

Step 4: Measure Height / Depth

From the top opening edge down to the bottom interior flat surface (for internal), or outside if you need external.

Pro Tips

- Always measure twice to confirm.

- Round up to the nearest 1⁄16 inch or a small fraction to ensure a little clearance.

- Be mindful of internal inserts or cushions; they may subtract from usable interior space.

- For consistency, always note whether your measurement is internal or external for future reference.

- Best Practices for Accurate Box Measurements

- Always measure in the same direction.

- Use the same tool in many boxes.

- You can measure many times

- Double-check is avoided by expensive errors.

- This is especially important when ordering customized packaging.

- Documentation of measurement for future orders

- Keep track of all box dimensions.

- Update notes if you change the product specifications.

Types of Boxes and How Measurements Differ

Different box styles require slight variations in how you interpret the measurement. Here are common types:

Regular Slotted Carton (RSC):

Measure the opening flaps area for L × W, then the depth inside for height. External size includes full walls & flaps.

Die-cut mailer boxes:

These often have overlapping lids or flaps. Measure internal usable depth (lid clearance) and total external folded box.

Folding cartons (paperboard):

Very precise measuring is needed because the product fit is tight. Use calipers if tolerances are ±0.5 mm.

Rigid setup boxes:.

They have thick walls. Always measure internal usable depth, not justthe outer box interior.

Tubes/cylinders:.

Here, you measure diameter (or internal diameter) and height (length). If irregular shape, record cross-section dimension.

Each style’s internal vs external difference is crucial for fit and quoting.

Must read: Detail Guide About the Types of Boxes

Measurement Units & Conversion Chart

Units in Use

U.S. Customary (inches) is common in the U.S. packaging and logistics industry.

Metric (centimeters or millimeters) is standard for international suppliers and design files.

Conversion

- 1 inch = 2.54 cm

- 1 cm = 0.3937 inch

- 1 mm = 0.03937 inch

| Inches | Centimeters |

| 1.0 in | 2.54 cm |

| 5 in | 12.7 cm |

| 10 in | 25.4 cm |

Use metric in design specs when dealing with factories abroad; in logistics, stick with the carrier’s required unit (often inches + pounds in the U.S.).

How to Choose the Right Box Size for Your Product?

Work with an Expert Packaging supplier

Collaborate closely with the custom box manufacturer, as they can provide expert advice. Thus, brands take their help to avoid normal errors during the measurement process.

Provide accurate Dimensions

Always measure the box in your intended orientation and give your supplier an accurate internal and external dimension.

Consider internal components

The box accounts for all elements, inserts, dividers, and padding inside it. These can affect the product's usable location and general fit.

Common Measurement Mistakes to Avoid

Here, I explain the most common mistakes you should avoid when measuring box dimensions.

- Measuring the wrong side first (e.g., swapping length and width).

- Confusing height and width in tall boxes.

- Ignoring flaps or liners when measuring this may mislead the external dimension.

- Not accounting for internal padding or inserts, which reduce usable space.

- Treating external = internal dimension (especially in thick-walled boxes).

- Relying on a single measurement, always double check.

- Avoiding these errors ensures accuracy and reduces surprises.

- Overpackaging

Using a large box can increase shipping costs due to its high dimensional weight. It also requires more storage space in warehouses and trucks. Over time, it can significantly increase operating expenses.

- Under packing

A too-small or dense box can pressure the product. The small size can increase the risk of damage during shipping and raise or tear the box, compromising its integrity. The correct-size packaging ensures that the products arrive safely and professionally.

Impact of Box Dimensions on Shipping

- Shipping Costs Based on Box Size

- Based on carriers such as FedEx, UPS, and DHL cost:

- Real weight

Dimension weight: calculated as (length × width × height) ÷ DIM divisor.

The importance of reducing space cannot be undermined. It saves you from higher shipping costs and any external or internal damage. So, always choosing the right box can reduce shipping costs.

International Shipping Considerations

International carriers use both the metric (cm) and imperial (inch) systems. Understanding how to measure box dimensions in inches or centimeters can help determine the right shipping cost.

When you send internationally, box dimensions become even more important. Different countries and carriers use their own DIM rules, maximum size limits, and overload limits. Incorrect measurements can lead to unexpected fees, customs delays, or rejected shipments. Hence, the exact box size may be necessary for even border crossing logistics.

You can choose the smallest box that safely fits your product and padding. Moreover, you can use box measurement calculators as online tools to compare options.

Dimensional weight (dim) and how it affects your costs

Dimensional weight prices are based on the space that a package takes instead of its actual weight. The carriers divide the length × width × × height with a specified separation (139 for inches or 5000 for centimeters). If the slow weight is greater than the actual weight, you are charged for a greater value, so customizing the boxing dimensions directly affects your delivery expenses.

Custom Box Dimensions: What Makes It Ideal?

There are various reasons that make custom boxes perfect for your products. Every product has a different size, shape, and design. So, the standard box does not fit each type. You can go for customization of packaging boxes when

- Your product has an unusual form.

- You need a brand-unboxing experience.

- Standard sizes provide space or poor protection.

- Benefits of Customizing Box Dimensions

- Better product protection

Custom box dimensions ensure the product fits perfectly inside. This reduces movement during shipping and the risk of injury, which means less packaging material.

Enhance Beauty and customer experience.

A well-equipped custom box looks smooth and professional, making unboxing easy and fun for customers. Plus, beautiful packaging leaves a permanent impression and focuses on expansion.

Increased brand recognition

Custom boxes can facilitate your logo, colors, and design elements. They help strengthen your brand every time a customer receives a package. Strong, constant branding creates loyalty and trust.

How to Get Accurate Custom Box Measurements?

When ordering a customized box, it is important to work closely with the package supplier. They can help you choose your product's length, width, and height. Always provide accurate measurements, and remember to account for things like posts or padding inside the box.

Common Mistakes to Avoid When Ordering Custom Boxes

Avoid making the boxing design very complicated, as it can slow production. Don't forget to leave enough space for safety and package material. In addition, make sure the flap is measured and properly designed to avoid appropriate problems.

How to Measure Special Packaging Types?

- Padded Mailers and Envelopes

- Length and width of boxes when they lie flat.

- Considered expansion if padded.

- Rigid Boxes (gift boxes, luxury packaging)

- Internal dimensions first.

- Add quotas to the lining or protective foam.

- Mailer -boxes and Subscription boxes

- They often have self-locking designs:

- Measure the interior dimensions carefully.

- Check both flat and overall conditions.

- Heavy Duty Boxes for industrial or delicate products

- Consider the Wall thickness.

- Reinforcement or cushioning.

- Double-checked measurements to ensure safety.

Conclusion

Exact Packaging dimensions are necessary to achieve success. They affect everything from product safety to shipping costs to customer satisfaction. Whether you work with standard sizes or customize your packaging, we help measure you properly to save money, reduce waste, and provide a professional product.

If you are struggling with form or require a customized solution, consider working with packaging professionals. Buy custom boxes with logo in the US to get specialist help to design the right fit for your products.

By following the above step-by-step guide, you will be well on your way to mastering the packaging dimensions and running more efficient, cost-effective operations.

Frequently Asked Questions:

Q: What is the correct order to measure box dimensions?

A: Always use Length × Width × Height (L × W × H) unless otherwise specified.

Q: How do I measure a box for UPS, FedEx, or USPS?

A: Use external dimensions, round up fractional inches (especially after Aug 18, 2025), then plug into (L × W × H) ÷ DIM factor, and compare with actual weight. See policies above.

Q: What is the difference between box size and box volume?

A: Size is L × W × H in linear units; volume is the cubic space. Volume (divided by divisor) gives dimensional weight.

Q: Can I use a phone to measure a box?

A: Yes, for rough estimates via AR measurement apps. But for precision (especially for custom boxes), always use tape, ruler, or calipers.

Q: How to measure a custom- or odd-shaped box?

A: Break it down: measure each face you need (e.g., for a triangular box, measure each side & height), document via a sketch or die-line, and clarify internal usable dimensions.

iCustomBoxes is a specialized print and packaging company based in the USA. We offer error-free printing, free design support, and unlimited customization. Start your printing journey with us, and we will customize the packaging in your preferred material, style, color, and size.